GARDEN

STRUCTURES

Garden structures and other outbuildings are soaring in popularity. With an increase in working from home, plenty of people are investing in home offices separate from the house to allow for an inspirational, but separate, working environment.

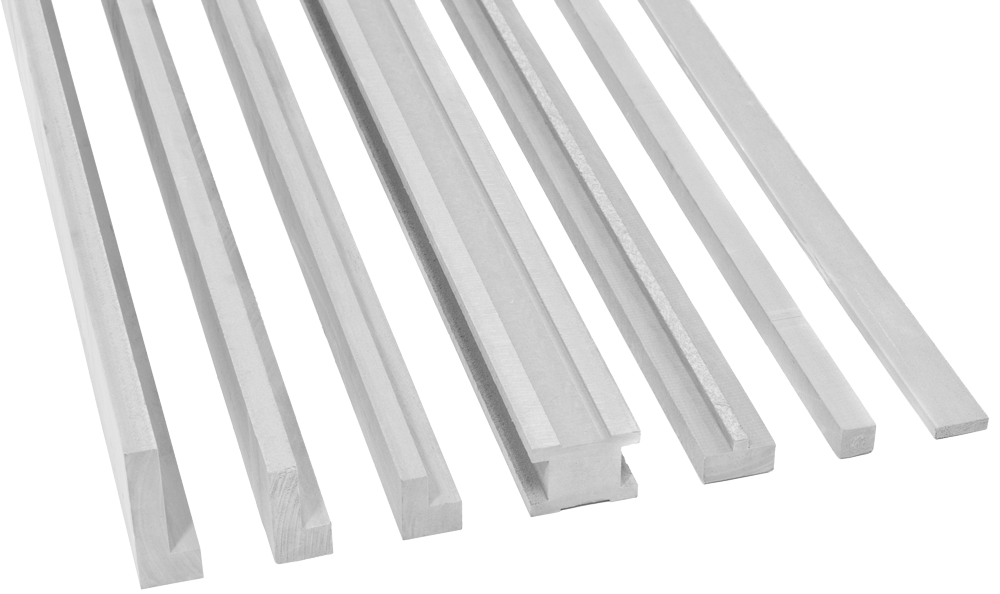

Rocal Extrusions produce a variety of different extruded plastic profiles for garden building manufacturers, in many instances to replace traditional timber components with longer lasting plastic alternatives.

PERFORMANCE

IMPROVED LIFESPAN

Unfortunately, many garden structures have a limited lifespan that will hinder homeowners’ enjoyment of them moving forwards.

Typically manufactured using timber, many garden structures require maintenance to prevent them succumbing to the elements and slowly rotting away.

In certain applications, replacing just a few timber components with a polymer alternative can drastically increase the lifespan of a garden structure and decrease the amount of maintenance required to keep them looking fabulous.

FOR GARDEN STRUCTURES

Many garden building manufacturers have chosen to increase the lifespan and reduce the maintenance required by their structures by replacing timber with TimbPlas.

As an engineered polymer replacement for timber, TimbPlas will never rot, swell or degrade in any way, making it ideal for use in products which are exposed to rain and sun all year round.

POLYMER BATTENS

Many of our customers in the Garden Building Industry have experienced costly aftersales issues due to moisture ingress across various sections of their structures.

Rocal Extrusions have developed a range of TimbPlas batten profiles that are designed to replicate the commonly used timber battens, making swapping timber for TimbPlas simple.

Examples of where TimbPlas has been used in favour of traditional timber lengths include:

• Structural framing for wall panels

• Cavity spacing battens within wall panels

• Framing around window and door apertures

• Construction of garden building bases

• Cladding battens

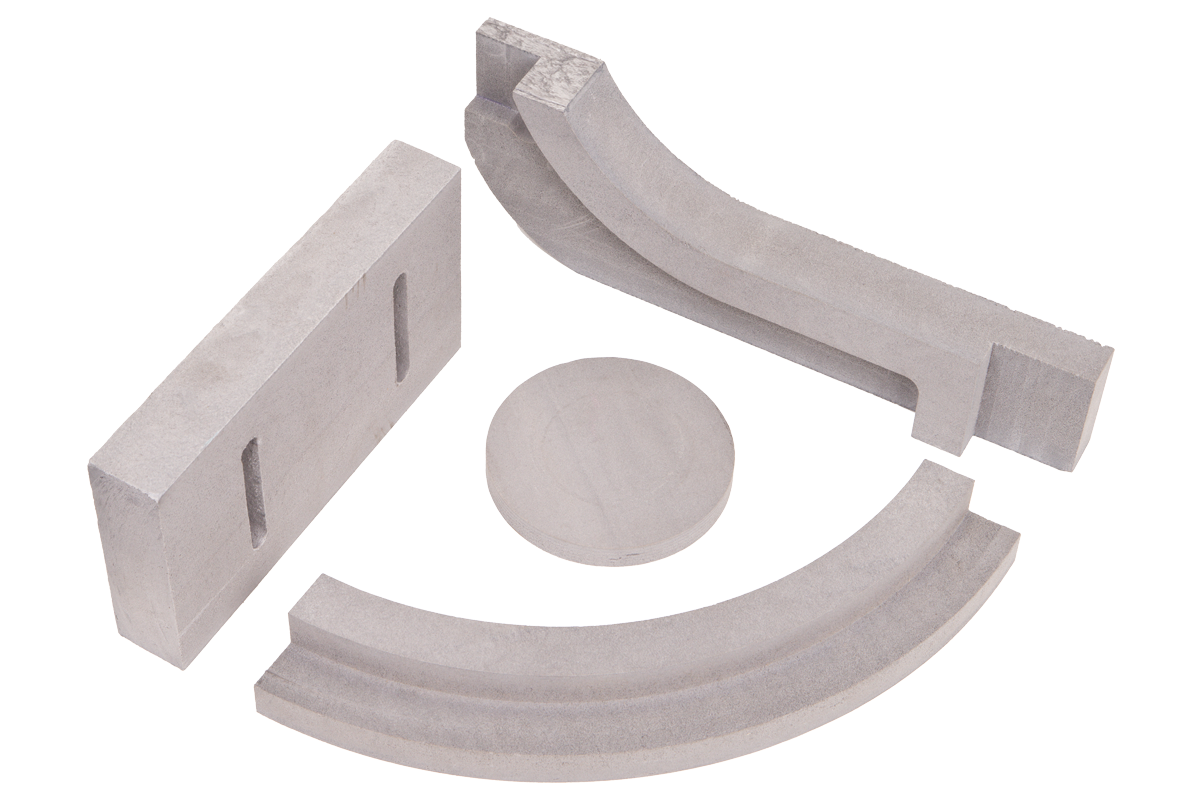

BESPOKE COMPONENT PARTS

Such is the versatility of TimbPlas, it can be cut, planed or machined into almost any shape or profile.

Examples of component parts we have specified for the Garden Building industry include:

• Structural framing for wall panels

• Cavity spacing battens within wall panels

• Framing around window and door apertures

• Construction of garden building bases

• Cladding battens

FOILED PRODUCTS

FOR GARDEN BUILDINGS

Every season design trends change in our homes and the garden building industry is no different. At Rocal Extrusions, we have experience sourcing the interior foil finishes that best represent consumer tastes each season. This allows us to produce high quality plastic extrusions that perfectly match the desired finish of our customers.

For the garden building industry we currently produce and wrap a wide variety of different extruded profiles, including:

• Finishing trims

• Corner concealing strips

Downloads

TIMBPLAS

PRESENTATION

Promotional brochure for the TimbPlas product including USPs and Case Studies.

TIMBPLAS

BROCHURE

Further promotional information on the TimbPlas product. Printed copies available on request.

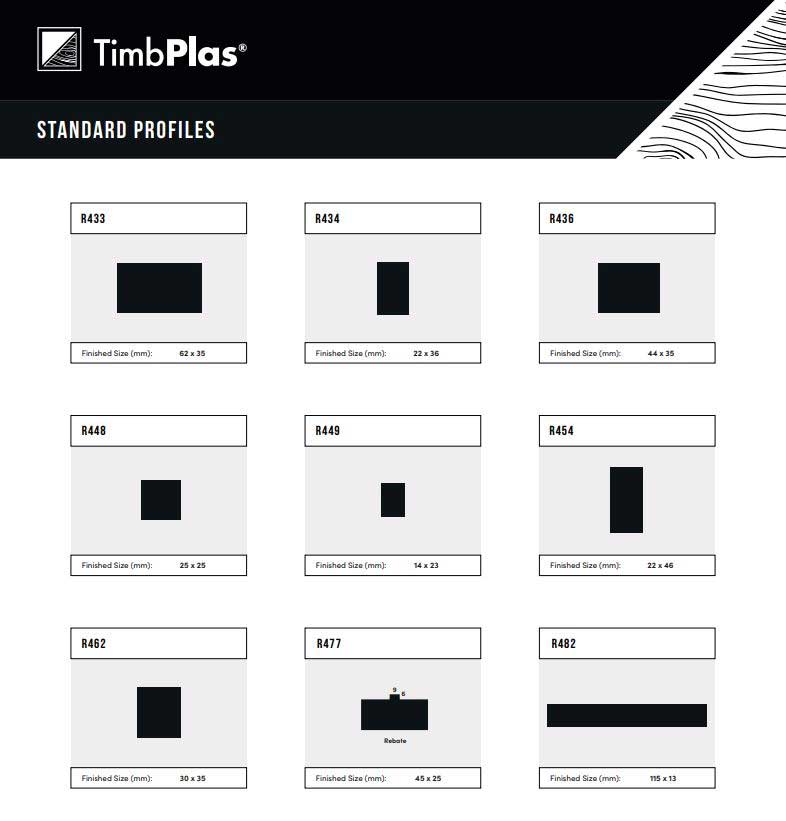

STANDARD

PROFILES

Our list of standard profiles that are readily available, with tooling already produced.

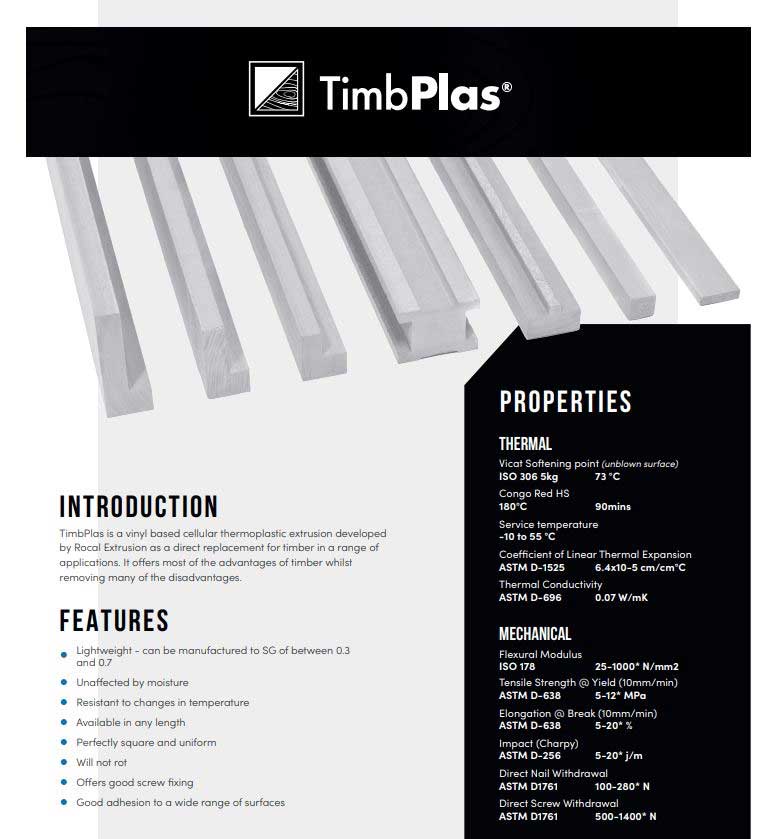

TECHNICAL

INFORMATION

Technical information on the TimbPlas product, including its properties and performance.