A POLYMER REPLACEMENT FOR TIMBER

It’s no secret that over time, wood will rot, swell, warp and degrade when exposed to moisture.

By replacing timber with TimbPlas on projects where moisture may cause problems in the future, you’ll see how it feels to truly fix and forget.

With its lifetime guarantee, TimbPlas offers you peace of mind as well as consistent engineered quality and versatility that wood simply cannot deliver.

It’s no secret that over time, wood will rot, swell, warp and degrade when exposed to moisture.

By replacing timber with TimbPlas on projects where moisture may cause problems in the future, you’ll see how it feels to truly fix and forget.

With its lifetime guarantee, TimbPlas offers you peace of mind as well as consistent engineered quality and versatility that wood simply cannot deliver.

Why  ?

?

UNAFFECTED BY MOISTURE

Even when permanently submerged, these profiles will retain their structural integrity – meaning they will outlast almost any product in which it is used.

LIGHTWEIGHT BUT STRONG

Offering similar levels of density and strength to softwood, TimbPlas is also lightweight. Making it ideal for projects where weight may be a consideration.

ADAPTABLE

& WORKABLE

MACHINE IT.

BOND IT.

SCREW IT.

PLANE IT.

TimbPlas can be worked with like timber but is long lasting like plastic.

MAINTENANCE

FREE

Not only does TimbPlas not require any form of treatment to make it stand the test of time, but it is also 100% maintenance free.

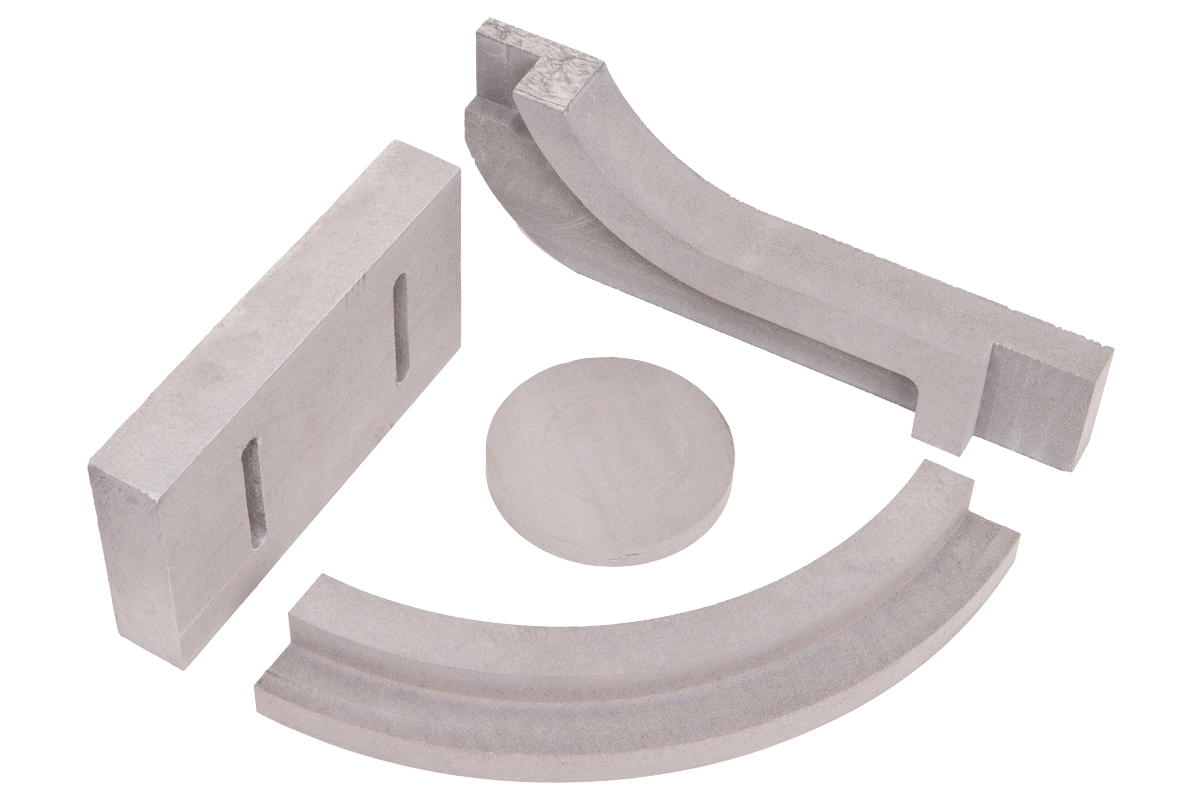

BESPOKE COMPONENT PARTS

Such is the versatility of TimbPlas that it can be machined into almost any shape or length. If you are looking for component parts that are lightweight, long lasting and maintenance free, TimbPlas is the ideal solution for you and your product.

Our in-house tooling and Product Development Team can take the cost and hassle out of designing your own bespoke profile.

Send us your drawing and we will provide a quote within 24 hours.

FREE

SAMPLE BOX

If you’re looking for a component that will stand the test of time and provide you with peace of mind, swapping timber for TimbPlas will show you how it feels to truly fit and forget.

We’d love to send you some physical samples of our product so you can see the consistently engineered quality and precision.

CASE STUDY:

LEISURE HOME

MANUFACTURER

In order to tackle costly aftersales issues associated with structural timber bowing and rotting, a well-known leisure home manufacturer chose to replace the traditional timber batons used within their wall cavities with TimbPlas.

This move has drastically improved the lifespan of their products and saved them considerable sums by reducing remedial issues.

ANY LENGTH

Such is the versatility of TimbPlas that is can be produced in almost any length or shape. Unlike natural timber, there are no limitations to the length we can produce other than the size of the vehicle used to transport it.

What’s more, you’ll enjoy consistent engineered quality across its entire length.

Sustainability

100%

RECYCLABLE

Not only can TimbPlas be manufactured using recycled material, but it can also be recycled itself at the end of its use.

Unlike natural timber, this polymer material will also outlast any product in which it is used.

ENGINEERED PRECISION

TimbPlas is an engineered product, meaning you will benefit from consistent quality throughout its length.

NO KNOTS.

NO TWISTING.

NO ROTTING.

ENERGY

EFFICIENT

TimbPlas offers a similar U-Value performance to softwood of the equivalent thickness.

Replacing your existing timber structure with this polymer material means no increase in heat loss and no thermal bridging.

Downloads

COMPANY

PRESENTATION

Promotional brochure for the Rocal Extrusions including USPs and Case Studies.

WRAPPING

OPTIONS

Catalogue of wrapping options and finishes available as an additional operation.

TIMBPLAS

BROCHURE

Further promotional information on the TimbPlas product. Printed copies available on request.

STANDARD

PROFILES

Our list of standard profiles that are readily available, with tooling already produced.