Case Study:

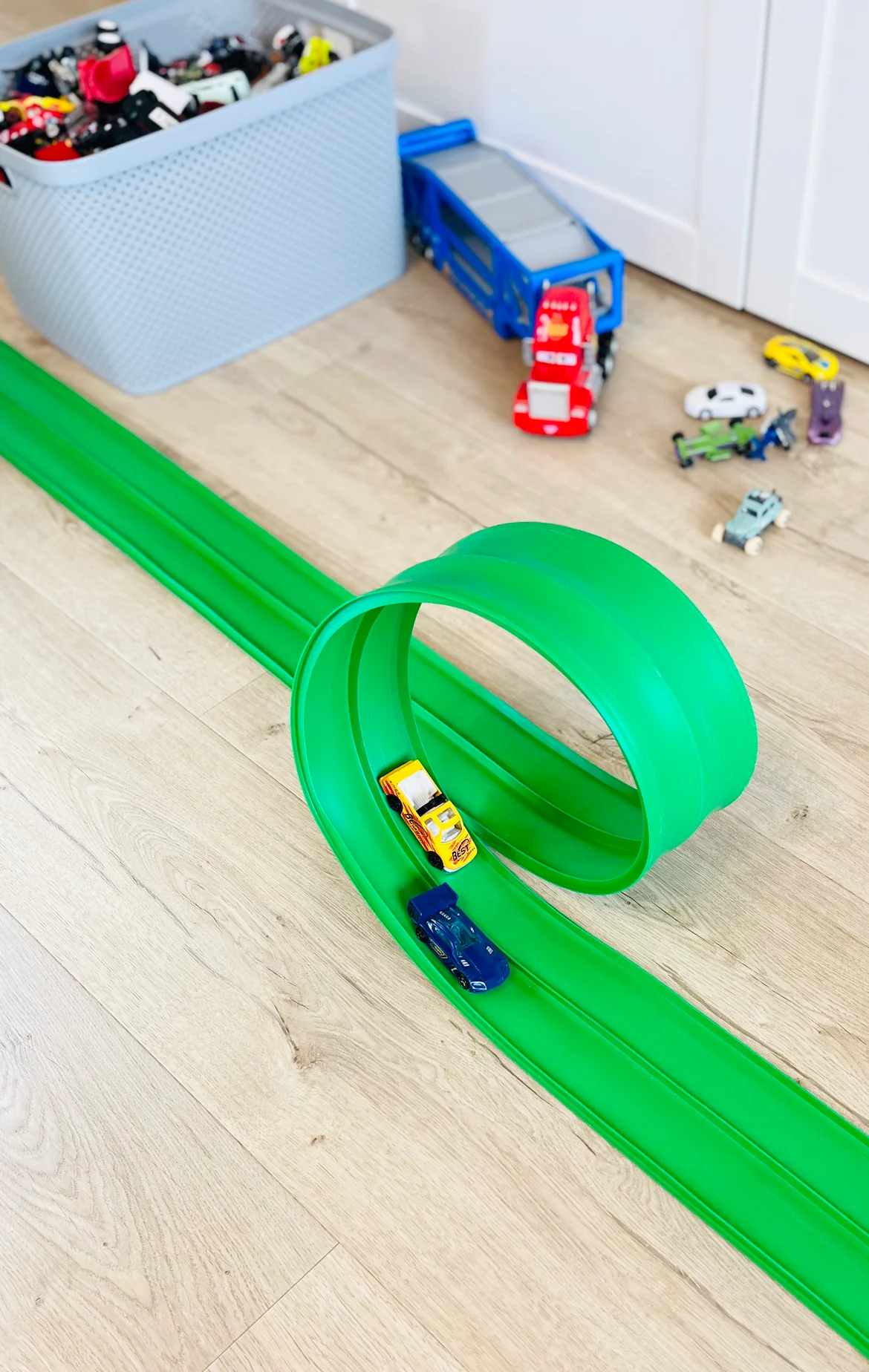

FLEXITRACK

Rocal Extrusions have been working with retailers of bespoke products for over a decade. During this time we have developed a solid customer base and a reputation for delivering quality products, on time and at reasonable prices.

Flexible

Plastic Extrusions

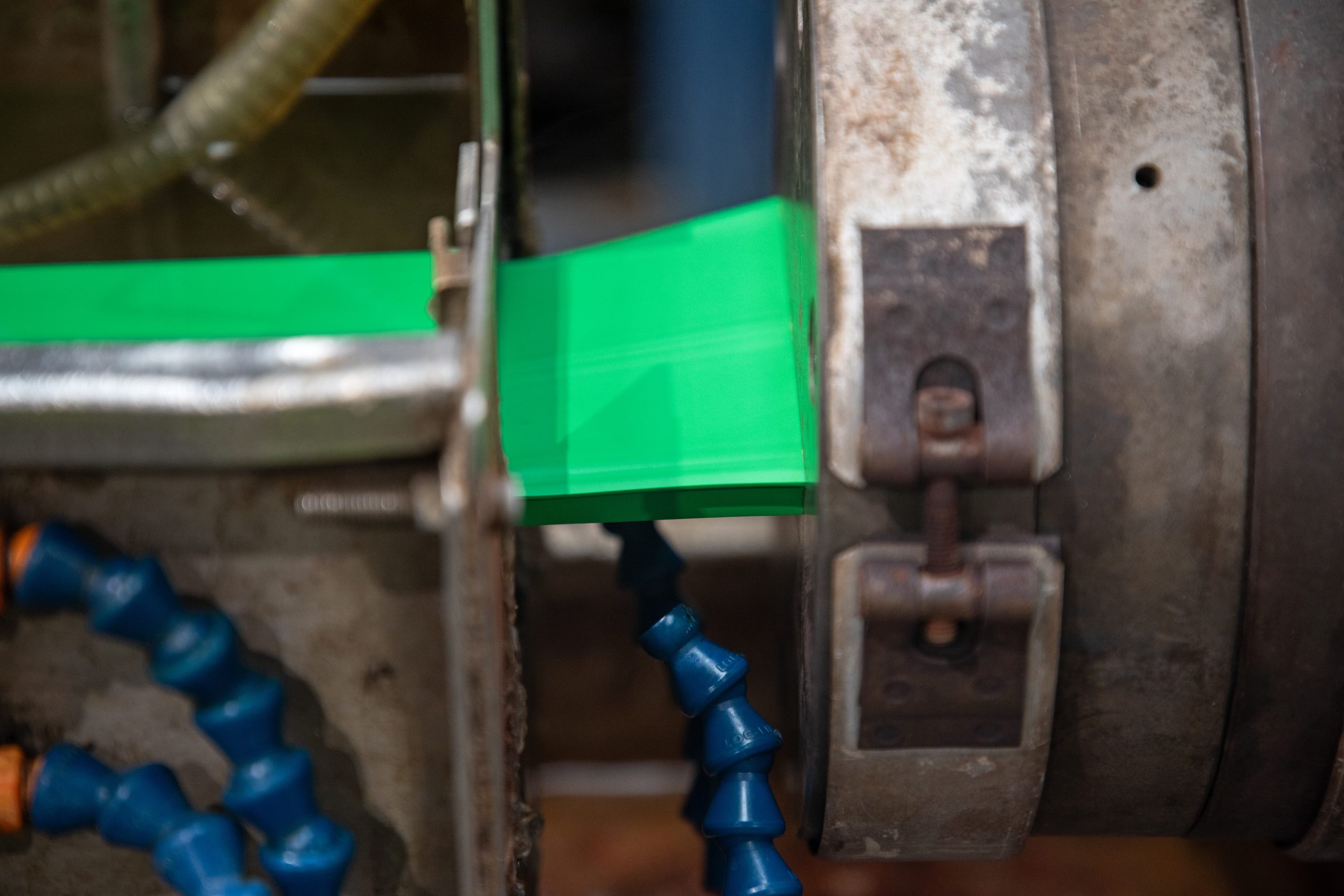

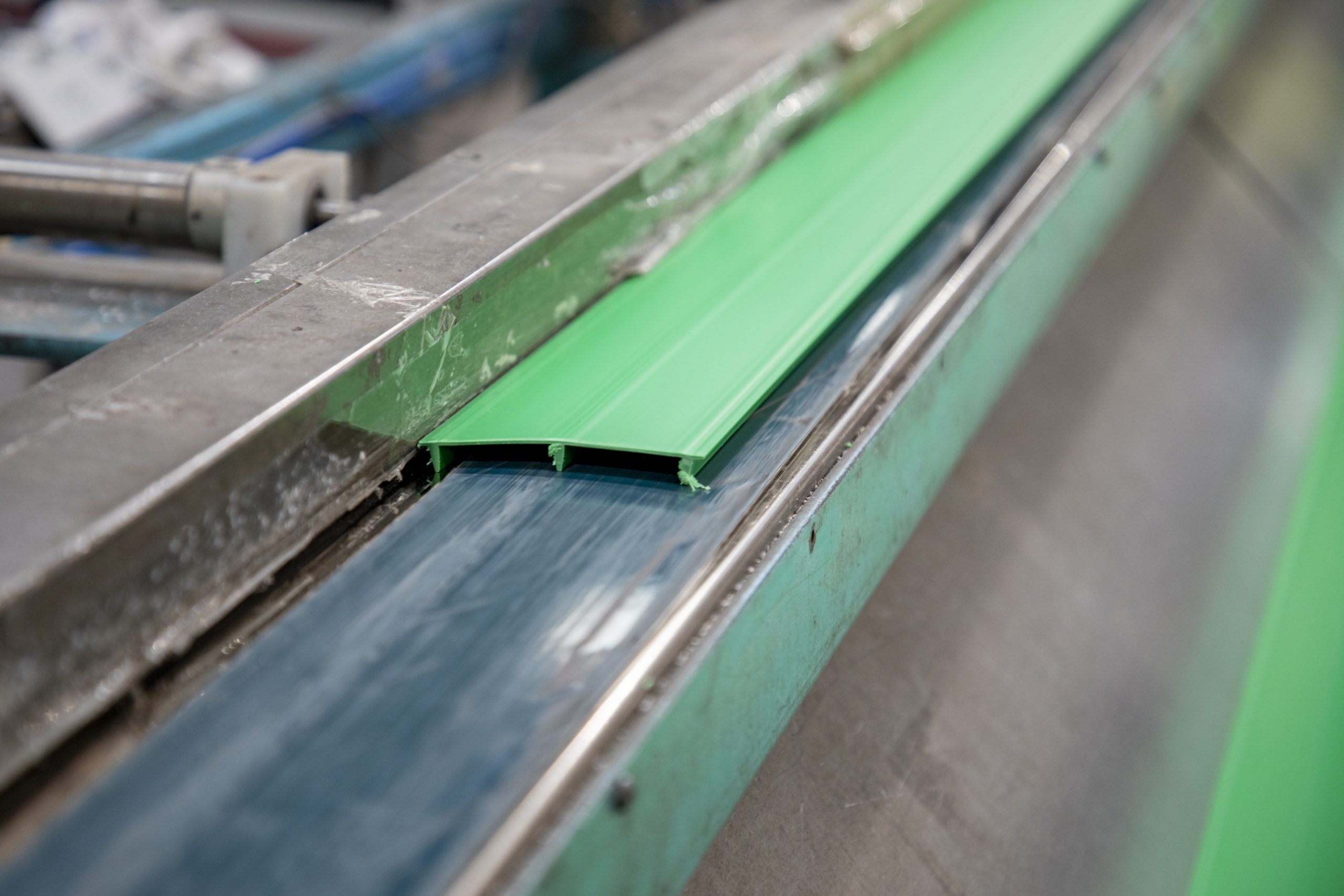

Bespoke extrusion projects allow for the creation of unique designs tailored to specific project requirements, addressing challenges or functionalities that standard extrusions may not fulfil. Specialised applications benefit from custom extrusions designed to optimise performance, whether in terms of durability, flexibility, or other desired properties.

For the independent manufacturers we currently produce a wide variety of different custom extruded profiles, with varying levels of:

• Rigidity

• Moisture Resistance

and more…

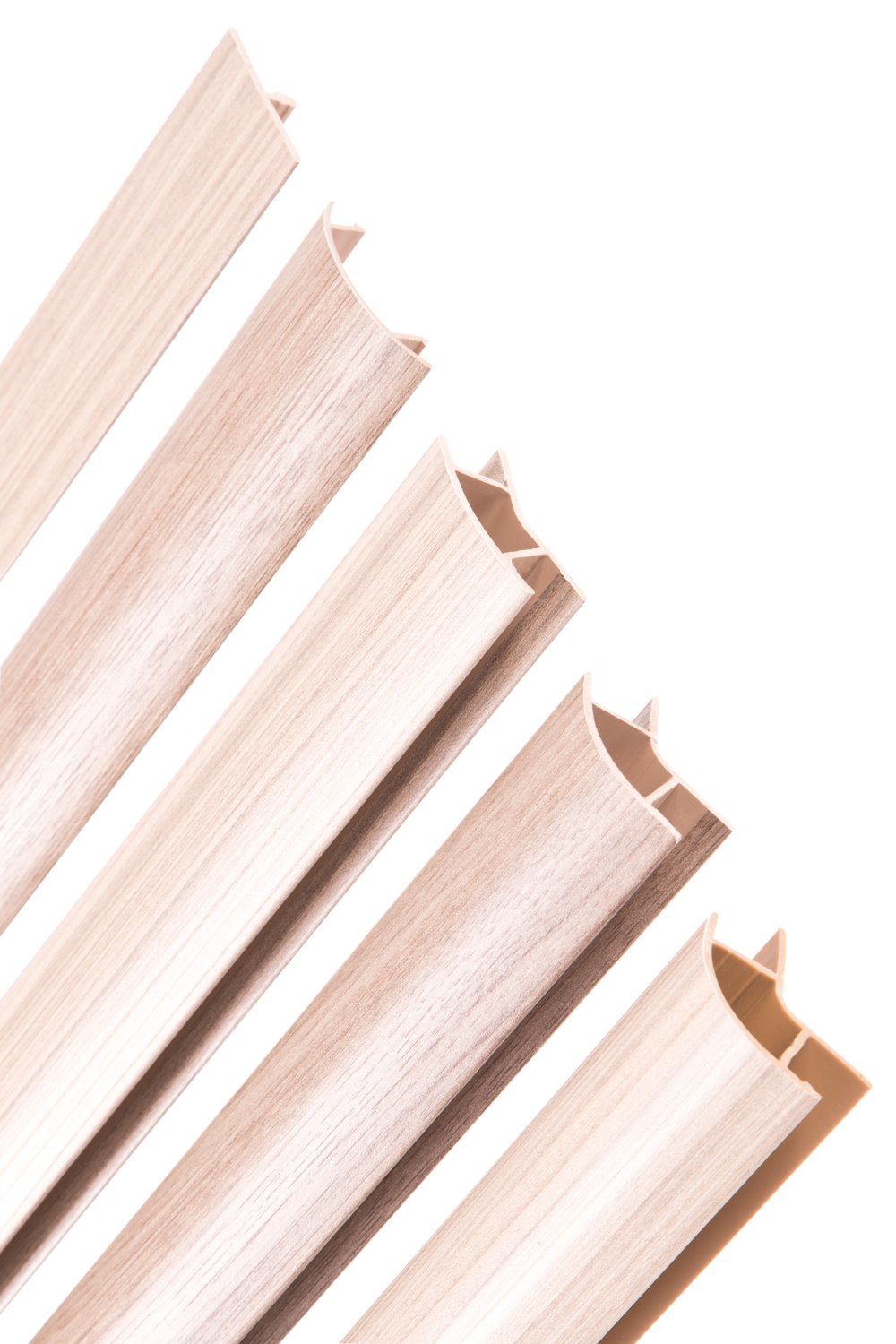

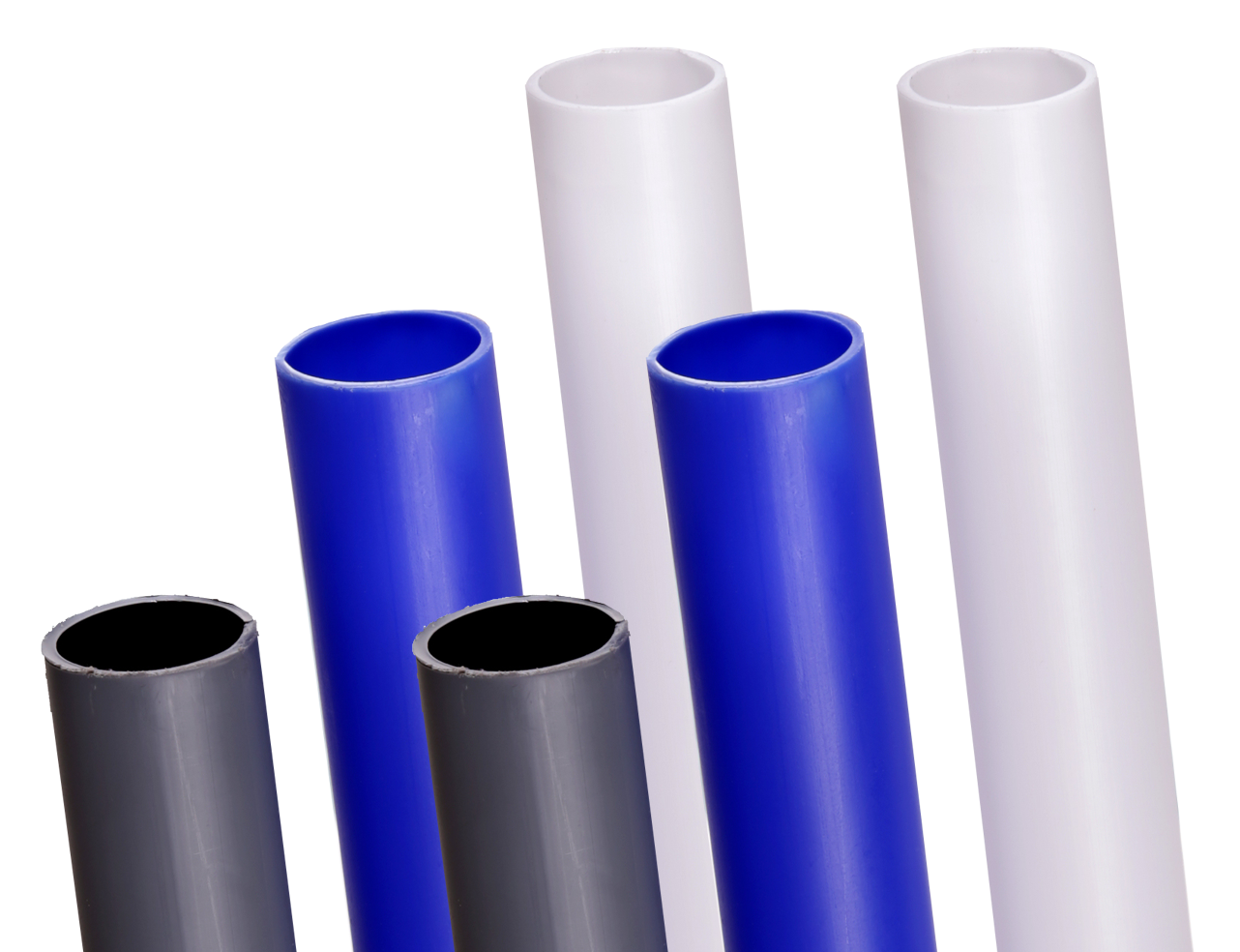

RIGID EXTRUSIONS

FOR PRODUCT MANUFACTURERS

Having successfully developed numerous products for independent and mass product manufacturers, Rocal Extrusions continues to be the go-to supplier for customers in the manufacturing, fenestration and leisure industries.

Thanks to our capacity for secondary operations, extruded components from Rocal Extrusions have contributed to increased product lifespans and reduced aftersales issues for our customers.

Custom Extrusions for the Manufacturing Industry

If you’re looking for the perfect component part for your product, Rocal Extrusions offers a range of services to help you find the perfect material and finish for your needs.

For a free, no obligation quote contact the Rocal Extrusions team, and start developing your new product today.

Downloads

COMPANY

PRESENTATION

Promotional presentation for Rocal Extrusions with information about our company and services.

WRAPPING

OPTIONS

Technical information on the TimbPlas product, including its properties and performance.

TIMBPLAS

PRESENTATION

Promotional brochure for the TimbPlas product including USPs and Case Studies.

STANDARD

PROFILES

Our list of standard profiles that are readily available, with tooling already produced.