Both PVC and uPVC are common materials used in the construction sector. From the manufacturing of pipes, doors and windows, to cladding, gutters and casings, down to fixtures and trims – the versatility of these materials is well known and understood. We’re sure we don’t have to tell you that! But is there a difference between them? It’s easy to assume that they’re the same thing, but there is a subtle distinction. Put simply, the two terms are defined as follows:

PVC stands for ‘polyvinyl chloride,’ whereas uPVC stands for ‘unplasticised polyvinyl chloride.’ As the names suggest, the addition of plasticisers to the process is what sets these two materials apart. Standard PVC contains plasticisers while uPVC doesn’t. Adding these to the polymer mix has an important effect on PVC products, making them softer and more flexible.

Because of its weather-resistant properties, uPVC is commonly used to manufacture window and door profiles. It won’t change shape under normal weather conditions but can be reshaped at very high temperatures. uPVC home improvements are a popular choice for their energy efficiency performance, which is superior to wooden or metal frames.

Rigid or Flexible Extrusions

Here at Rocal Extrusions, we can produce both rigid and flexible plastic extrusions based on your application and requirements. Contact our team today or send us a technical drawing and we’ll come back to you with the next steps.

Once we understand your desired application, our team can get to work developing and specifying the ideal blend of polymer to deliver a flexible plastic extrusion that perfectly meets your needs. Depending on your application, we can extrude flexible plastic profiles using either PVC or LDPE (aka, low-density polyethylene, known for its resistance to impacts and moisture). You can count on our experience and expertise to create the right bespoke product for you.

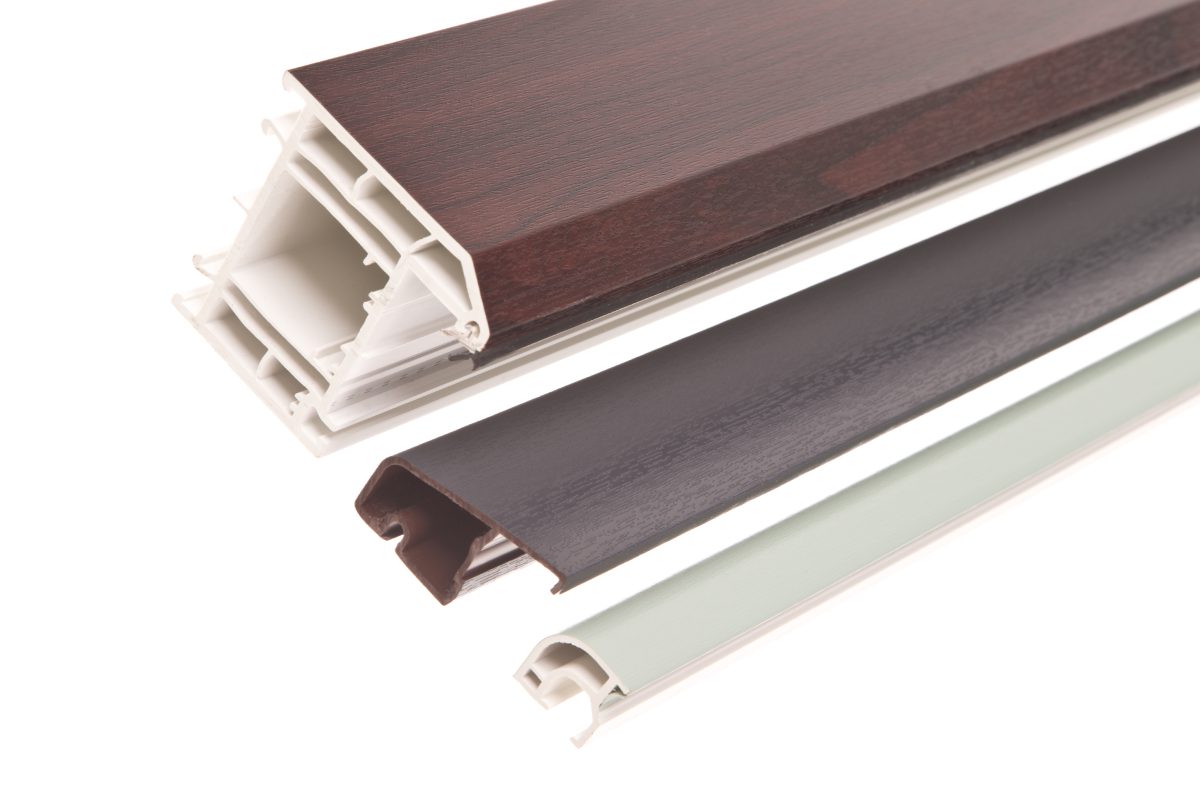

We manufacture rigid plastic profiles in a wide variety of different shapes, colours and finishes to meet the desired specifications and applications of each of our valued customers.

According to your specification and dependent on its application, we can extrude rigid plastic profiles with thermal properties, flame retardancy, impact strength and both UV and chemical resistance.

For more information on our products and which is the right fit for you, please contact us by phone at 01652 225 200 or via our online contact form.