What is Profile Wrapping?

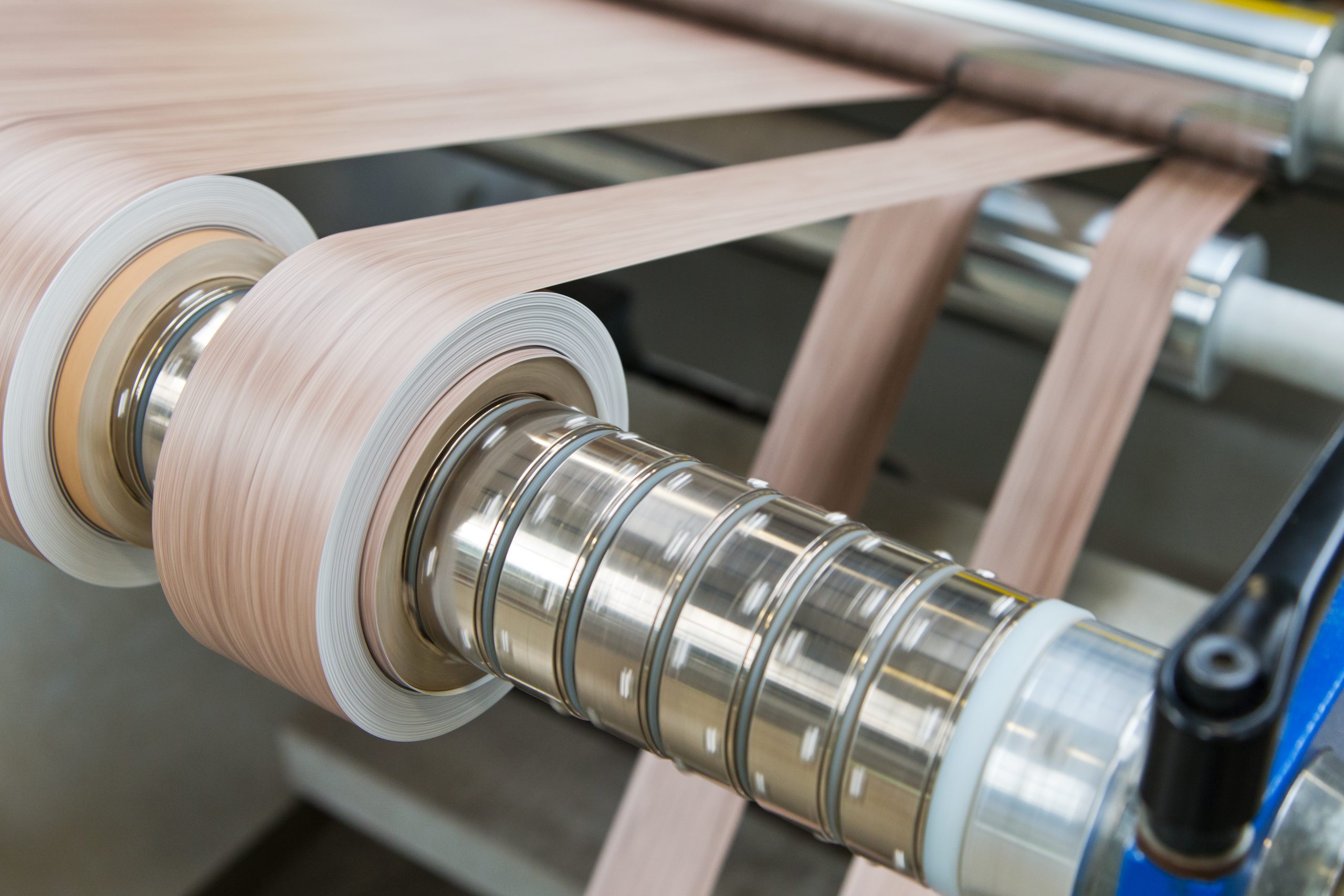

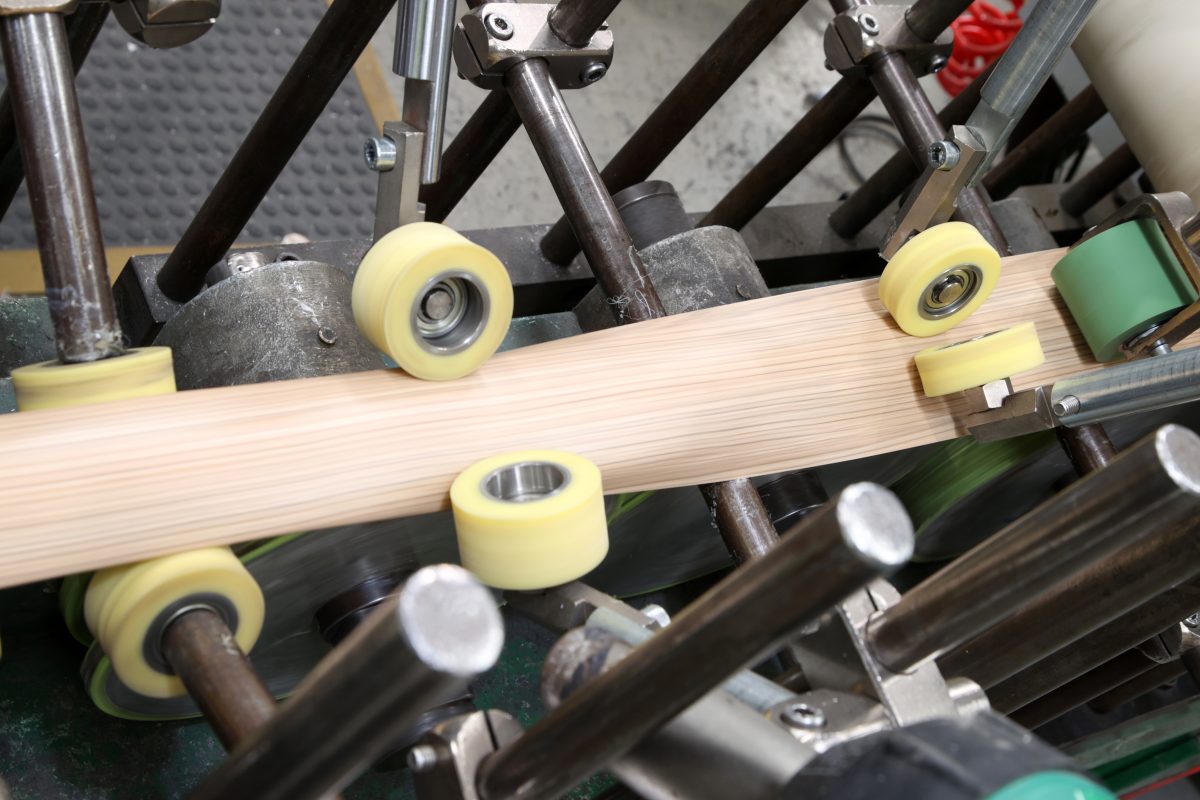

Profile wrapping is a surface finishing method that comes in a variety of materials. It allows extruded plastic products to have different colours, textures, and finishes. The process is done by laminating a wet adhesive material on a substrate surface which is then pressed down by pressure rollers. It’s a simple process that’s faster than other finishing methods, allowing for an even faster turnaround.

Rocal Extrusions offers a wide choice of colours and textures, as well as wood grain and fabric effect finishes, for both internal and outdoor applications.

Quick Turnaround

Unless we’re developing something unique and bespoke to your needs, our profile wrapping is very easy to manufacture thanks to the on-line and off-line wrapping machines we have in-house. Although there’s a very extensive range of foil wraps, the manufacturing process for each profile wrap is fast and concise, ensuring a speedy delivery.

Improves Durability

It’s no secret that at some point, wooden exterior furnishings will eventually absorb moisture, bow, rot, and cause draughts. A wrapped profile provides an extra layer of protection that protects your product from the elements.

A Wider Range Of Colours & Textures And Bespoke Design Styles

Arguably the most obvious reason why people use profile wrapping is for display purposes.

Though there is already a wide range of interchangeable texture and colour combinations, you may find that there isn’t a finish that suits you. Thankfully, we can develop and produce custom plastic extrusions laminated to your exact requirements faster and more cost-effectively than the competition.

What Is Profile Wrapping Used For?

Residential Applications

Plastic extrusions are frequently wrapped to mimic the colour and sheen of leather, wood, and other material surfaces. These surfaces can also be embossed to give an upscale appearance and feel. As a result, we’re able to wrap custom profiles for indoor and outdoor use:

- Indoor use

Skirting board, office furniture, decorative applications, papered connection strips for internal wall panels, and more. - Outdoor Use

Ideal for window profiles and window sills, rain deflectors and most other PVC profiles, garden structures, and more.

Industrial Use

Rocal Extrusions sits as the go-to supplier for industry leaders in many sectors, including but not limited to:

- Transport

In the transportation industry, the majority of our work is for car, van, and truck manufacturers. We manufacture plastic profiles that are rigid or flexible and are utilised as exterior finishing trims, lighting strip surrounds, cable coverings, and edgings for car doors. However, we also provide profile wrapping for railways and airlines. Producing plastic profiles that are used to join floor and wall panels, cover lighting strips and cables, and border luggage storage racks. - Healthcare

The healthcare industry uses our medical plastic extrusions for a wide range of purposes. Accuracy is crucial in the manufacturing of products such as sterile wall panelling connection strips and test and swab tubes. - Kitchen and Bathroom

Bathrooms and kitchens are often damp spaces that need to be cleaned frequently to maintain sterility. In contrast to other materials, plastic extrusions are quick and simple to clean, and they never rot, swell, or break down when exposed to dampness.

These are just a few of the many

When it comes to profile wrapping, Rocal Extrusions sits as the go-to supplier for industry leaders in Fenestration, Motorhome, Caravan, and Construction sites.

To view our Wrapping options brochure please contact us at 01652 225200 or email sales@rocalextrusions.co.uk