22 July 2024

Custom Plastic Extrusion: Tailoring Solutions for Diverse Industries

In today's fast-paced and ever-evolving world, industries are constantly seeking innovative solutions to meet their unique needs. One such solution that has gained significant popularity is custom plastic extrusion. This process allows for the creation of bespoke plastic profiles and shapes that are tailored to specific requirements, offering a wide range of benefits across various industries. Here at Rocal Extrusions, we specialise in providing custom plastic extrusion solutions for fenestration, automotive, leisure and construction industries, among others.

Custom Plastic Extrusion

Versatile and Precise Engineering

Custom plastic extrusion involves the manufacturing of plastic profiles and shapes by pushing molten plastic through a die to create a continuous length of plastic with a consistent cross-section. This process allows for the production of complex shapes and geometries that are not easily achievable with other manufacturing methods. At Rocal Extrusions, we utilise state-of-the-art technology and skilled employees to ensure precision engineering and high quality products.

Tailored Solutions for Every Industry

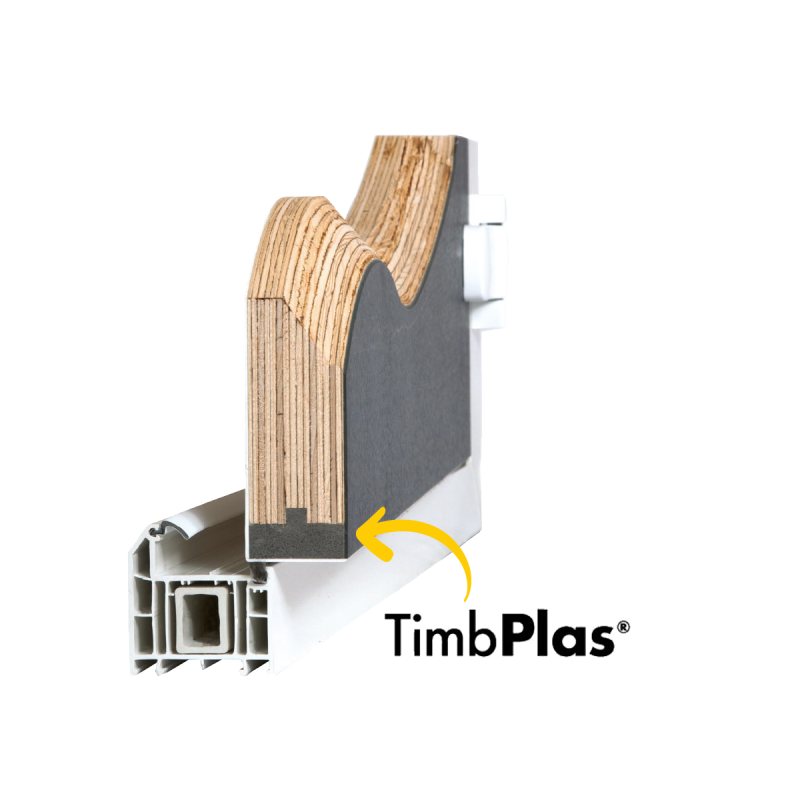

One of the key advantages of custom plastic extrusion is its versatility. We offer a wide range of plastic materials, including our own TimbPlas material, which is specifically designed to address moisture ingress issues. TimbPlas comes with a lifetime guarantee, making it an ideal choice for applications where durability and weather resistance are crucial. Whether it's rigid or flexible plastic extrusions, co-extruded profiles, standard profiles or tubing, we have the expertise to create custom solutions tailored to the specific requirements of each industry.

Enhancing Fenestration Performance and Aesthetics

The fenestration industry greatly benefits from custom plastic extrusion. Windows and doors are essential components of any building, and the use of custom plastic extrusions can enhance their performance and aesthetics. We offer a range of fenestration products, including window and door profiles, gaskets, weatherstrips, and glazing beads. These custom plastic extrusions provide excellent thermal insulation, soundproofing and weather resistance, ensuring energy efficiency and comfort in homes and offices.

Driving Innovation in the Automotive Industry

The automotive industry is another sector that can benefit from custom plastic extrusion. We can create custom plastic profiles for automotive applications, such as interior trims, seals, gaskets, and decorative elements. These plastic extrusions offer lightweight alternatives to traditional materials, reducing the overall weight of vehicles and improving fuel efficiency. Additionally, plastic extrusions can be designed to meet specific safety and performance requirements, making them an ideal choice for automotive manufacturers.

Enhancing Performance and Appearance in the Leisure Industry

The leisure sector also relies on custom plastic extrusion for various applications. We can create bespoke plastic profiles for leisure products, such as caravan trims, awning rails, and boat fenders. These plastic extrusions offer excellent durability, weather resistance, and aesthetic appeal, enhancing the overall performance and appearance of leisure products.

Durable and Cost-Effective Solutions for the Construction Industry

In the construction industry, custom plastic extrusion plays a vital role in creating durable and cost-effective building materials. We can produce plastic profiles for applications such as cladding, roofing, flooring, and fencing. These plastic extrusions offer excellent resistance to moisture, UV radiation, and chemicals, ensuring long-lasting performance in demanding construction environments.

Collaboration, Innovation and Sustainability

Here at Rocal Extrusions, we stand out for our commitment to quality, innovation and collaboration. With over a decade of experience in the industry, we have built a reputation for delivering high-quality products and providing exceptional customer service. Our team of experts is dedicated to understanding the unique requirements of each industry and working closely with clients to develop tailored solutions that meet their specific needs.

In addition to our custom plastic extrusion services, we also offer foil wrapping, secondary operations, custom tooling, and technical design support. We have the expertise to address complex design challenges and provide efficient and cost-effective solutions. Our commitment to sustainability is evident in our efforts to minimise waste, reduce energy consumption, and recycle materials whenever possible.

If you are looking for custom plastic extrusion solutions for your industry, you can count on us. Our extensive experience, technical expertise and dedication to customer satisfaction make us a reliable partner for all your plastic extrusion needs. Contact Rocal Extrusions today to discuss your requirements and request a quote. Our team of experts will be happy to assist you in finding the perfect custom plastic extrusion solution for your industry.